Overview

Polytronics Enterprises LLP, a leading manufacturer and distributor in the electronics sector, was seeking an integrated ERP system to unify its sales, inventory, procurement, manufacturing, and finance processes. The goal was to enhance operational visibility, streamline procurement cycles, and strengthen financial reporting and compliance.

Our team implemented ERPNext with key modules tailored to their business functions, enabling end-to-end digital transformation and data-driven decision-making.

Business Challenges

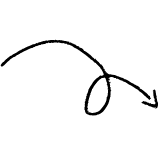

Before ERPNext implementation, Polytronics faced several operational bottlenecks:

- Manual reconciliation of inventory with purchase and sales data

- Fragmented lead management and customer engagement tracking

- Lack of centralized data for real-time financial insights

- Limited workflow control across procurement, production, and sales

- Delayed reporting for operations and performance metrics

Key Pain Points & Solutions

1. Maintaining Profit Margins

Challenge: Difficulty ensuring minimum profit margins due to manual pricing and fluctuating costs.

Solution: ERPNext automated margin calculations, enforced minimum selling price thresholds, and provided real-time alerts to prevent loss-making transactions.

2. Real-Time Stock Visibility for Field Sales

Challenge: Sales executives lacked instant access to inventory data, leading to missed opportunities and poor customer experience.

Solution: ERPNext’s mobile-friendly interface enabled real-time stock visibility, empowering sales teams to confirm availability and close deals on the spot.

3. Inefficient Purchase Order (PO) Approval Workflow

Challenge: Manual PO approvals caused delays, errors, and compliance risks.

Solution: ERPNext centralized and automated PO workflows, ensuring faster approvals, audit trails, and compliance adherence.

4. Overstocking and Buffer Stock Issues

Challenge: Excess inventory tied up capital and increased carrying costs.

Solution: ERPNext’s Auto Re-Order engine optimized stock levels, while Stock Ageing reports and multi-warehouse transfers reduced overstocking.

5. Import Document Tracking

Challenge: Manual tracking of import documents led to delays and compliance risks.

Solution: ERPNext provided a centralized, mobile-accessible platform for document management, ensuring real-time visibility and compliance.

6. Collaboration and Remote Access

Challenge: Lack of collaboration tools and inability to access systems remotely.

Solution: ERPNext’s cloud-based architecture enabled seamless collaboration and anytime, anywhere access.

Impact & Results

- Operational Efficiency: Reduced manual processes and approval delays by 70%

- Financial Control: Improved margin enforcement and pricing accuracy

- Inventory Optimization: Lowered excess stock by 30%, freeing up working capital

- Customer Experience: Enhanced responsiveness and trust through real-time data access

- Compliance: Streamlined import documentation and audit readiness